One of the two most important high barrier polymers used for food packaging applications is ethylene vinyl alcohol (EVOH).

EVOH semi-crystalline copolymer is known to be an excellent barrier against oxygen, dioxide and aroma permeability. It is especially important for refrigerated and shelf-stable foods where oxygen deteriorates the quality of packaged products and reduces their shelf life.

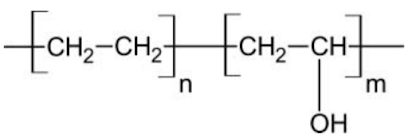

The copolymer composition (i.e., relative amounts of ethylene and vinyl alcohol) affects properties of EVOH copolymers such as gas barrier, mechanical properties, water vapor transmission, etc., and hence influences EVOH processing and end use applications.

EVOH has a far better oxygen barrier than PVDC (polyvinylidene chloride) when dry, that is, at 0% relative humidity (RH).

The attractive thermoplastic polymer is used for active packaging because of its biodegradability and environmental-friendly properties as well as compatibility with the human body.

Ethylene vinyl alcohol